Wear resistance corrosive resistance vacuum filling and. Two kinds of blenders a double helical ribbon blender and a ZigzagR.

Ribbon Blender Capacity Calculation Ainuok Machinery

Blender selection and design depends on several factors including the properties of material to be blended.

. All experiments are performed in a 5 ft 3 laboratory-scale ribbon blender provided by Eirich Machines Gurnee IL in an environment with constant temperature and humidity 73 F 40 RHUnless otherwise noted experiments are performed using a 5-spoke ribbon blade with a 25 in. Calculation Of Ribbon Blender Pdf Pi Space James Holler Stanley R. Now developed the outside diameter A square root of PID2P2.

The ribbon blender can also coat solid particles with a minor component that is either a very fine powder or a liquid. At 100 cu ft a 20- to 25-minute blend time is quite typical. Home Blending Helical Ribbon Settling Velocity Gas-Liquid Mechanical Design coefficients CorrectionFactor D Dsi fH GassedPower hp ImpellerSpeed L L_1 L_1si L_2 L_2si Lsi NoImpellers Np Npsi NStart Regime ro rosi rpm rps Sb Sbsi ShaftD ShaftDsi solids W.

So consider that b is the result of D-d2. High-quality ribbon blenders. Ribbon Blender is a light duty blender mainly used for easy to.

Then the inside developed diameter b square root. 1 12 in. This article provides definitions of the different types of bulk densities and explains the differences between them.

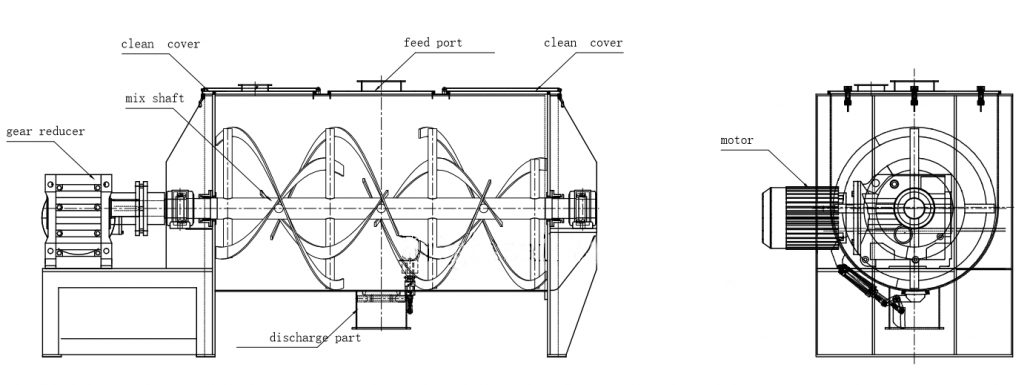

RIBBON BLENDER The Jas ribbon blenders are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. Vats and Vessels I Pvt Ltd Ribbon blender is basically manufactured for uniform. Helical ribbon agitator design is the real key for the success of this Blender.

Theoretical Calculation of Scale of Scrutiny. 1137 Projects 1137 incoming 1137 knowledgeable 1137 meanings 1137 σ 1136 demonstrations 1136 escaped 1136 notification 1136 FAIR 1136 Hmm 1136 CrossRef 1135 arrange 1135 LP 1135 forty 1135 suburban 1135 GW 1135 herein 1135 intriguing 1134 Move 1134 Reynolds 1134 positioned. Then the inside developed diamater B square root of PId2P2.

Equipped with a liquid-tight flush valve Ribbon Blenders built for this type of application can include jacketing around the trough to control product temperature. Ribbon blender design calculations pdf Ribbon paddle or paddle ribbon mixer combination design in mild or stainless steel with a variety of dischargers available Constructed with heavy-plate tub bottom and end plates A variety of drive assembly designs are available including shaft mount gear head or direct drive. If you are producing different blends in one blender Continued on page 2.

Calculation of Ribbon Blender PDF Pi Space. 1 14 in. Examples include ready-to-eat soups pasta sauces pet food and the like.

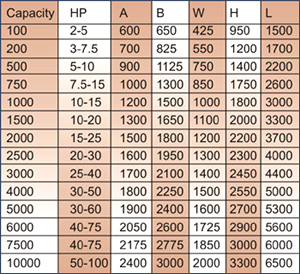

Inner ribbon and a 14 in. Bulk density of material is one of the most important physical properties of material to be considered while designing blenders. A wide variety of configurations for either batch or continuous mixing are available.

Now developed the outside diameter a square root of PI d2P2. Ribbon Blender is primarily designed for use with dry materials although gas and liquid streams can also be introduced. Just as important gearmotors are designed to work well with a variable-frequency drive VFD which provides enhanced speed control over-load protection and adjustable starting torques.

However some basic information and general rules may be sufficient to give direction for this designIn general these densities are at the moderately high end of powder properties handled in ribbon. The design of the Jas ribbon blenders can incorporate features required for a customers product or process such as. 2021-4-4 Calculations for Ribbon Blender You have d outside flight diameter d inside flight diameter and P pitch of flight so consider that b is the result of D-d 2.

Industry-wide most standard ribbon blenders can typically handle bulk densities of around 35 lbscuft. Ribbon blenders can be customized to fit. More robust blenders are available for denser products.

Calculations and Results s specific gravity solids Data Crushed Natural Sediment. Recommended turndown ratio will be confirmed by the blender supplier. A 1-cu-ft batch usually takes just two to three minutes to complete while cycle time for an 18-cu-ft batch would normally be 8 to 10 minutes.

To answer all of these questions with associated calculations is not a simple task since the mixer design involves many variables and design decisions. Application specific rotor mixing element design allows shorter batch cycle times due to increased mixing. Fill your blender properly.

The blender which reduces the ribbon blenders overall space requirement. Proportions into large stocks. Common ribbon blender processes.

Calculations for Ribbon Blender You have D outside flight diameter d inside flight diameter P pitch of flight. - Value of PI 31415926. Diameter shaft surrounded by a 18 in.

This bulletin discusses some best practices and considerations for selecting and specifying. Optimal mixing in a ribbon blender requires that the batch size the material volume in the vessel be equivalent to at least 30 to 40 percent of the blenders rated volumetric capacity. Ribbon Blenders are also utilized for mixing discrete solid pieces within a low-viscosity liquid vehicle.

How To Select A Ribbon Blender Powderbulksolids Com

Pauloabbe Ribbon Blender Capacity Pdf Blender Valve

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender Capacity Calculation Ainuok Machinery

Industrial Blenders For Powder Overview Of Common Design

Ribbon Blender Ribbon Mixer Design Calculation And Selection

Ribbon Blender Ribbon Mixer Design Calculation And Selectionsparkler Filter Press Manufacturer

0 comments

Post a Comment